E2 Carbon Fiber Wheels

The first and only single-piece carbon fiber wheel engineered and built in the USA.

Made with advanced innovative tailored fiber placement (TFP) and high-pressure resin infusion technology, the E2 wheel combines performance, durability, efficiency and innovation with the beauty of carbon fiber to deliver a first-of-a-kind aftermarket wheel.

E2 Carbon Fiber Wheels:

By the Numbers

-

Weight: 17 pounds

-

Rating: Vehicles up to 6,800 lbs (rated by axle)

-

Size: Available for order now in 19x8.5”

Acceleration

The lighter the wheel, the lower the rotational inertia – resulting in less force required to move the wheel forward. As a premium carbon fiber composite wheel, the E2 saves a significant amount of weight compared to aluminum and steel wheels. Testing has demonstrated that a 10lb weight saving per wheel translates into faster lap times of as much as 5.3%.

Braking

Simply put, lighter objects require less work to slow and stop. The E2 carbon fiber wheel is up to 45% lighter than equivalent steel or aluminum wheels. Testing has demonstrated that the E2 wheel can reduce braking and coasting distances from 60-1 mile per hour by as much as 3.6%.

Handling

Reducing unsprung weight minimizes the suspension’s effort to keep your wheels firmly on the road surface. Each E2 carbon fiber wheel removes up to 10 lbs of unsprung weight from the system, allowing the suspension to perform that much better. The resulting improvement in tire contact leads to enhanced steering response and sharper handling. Whether on the road, the track, or both, E2 carbon fiber wheels will take your driving experience to an entirely new level.

Road Test - Passed

Years of prototype testing have led to the development of the most technologically advanced wheel ever produced – the E2. Through highly advanced modeling with finite element analysis, ESE’s composite engineering team is able to predict how wheels will react in a plethora of real-world scenarios. Armed with that extensive data, ESE’s wheels are then put through their paces in both the lab and field, with the results being validated for strength, safety and performance. Read the details of the Proving Grounds testing.

Radial Impact Test - Passed

The radial impact test assesses the stability of the wheel against severe damage or failure when driving through potholes or over large obstacles. Understanding that streets and highways aren’t always pristine, the E2 wheel has been rigorously tested to endure typical road hazards and proven to outperform comparable steel and aluminum wheels. See the Radial Fatigue Report.

Curb Impact Test - Passed

The curb impact test is a crucial test that evaluates the effects of repeated impact against a static surface, simulating a vehicle hitting a curb or other fixed object at a predetermined rate of speed. Even at low speed, curb and wheel contact can generate large impact forces. The E2 carbon fiber wheels are designed and thoroughly tested to resist failure in damaging situations such as curb impacts. See the Curb Impact Report.

SAE J3204 Tested

The E2 is fully tested and pending certification under SAE J3204, the new composite wheel recommended practice. ESE is working closely with the SAE to help define the standards and set the benchmarks for composite wheels. The E2 carbon fiber wheels from ESE actually exceed the minimum SAE recommendations. Similar to metal wheels, the SAE’s recommendations for composite wheels address durability through various fatigue and impact tests. The SAE also added new requirements to account for environmental effects that are unique to composites.

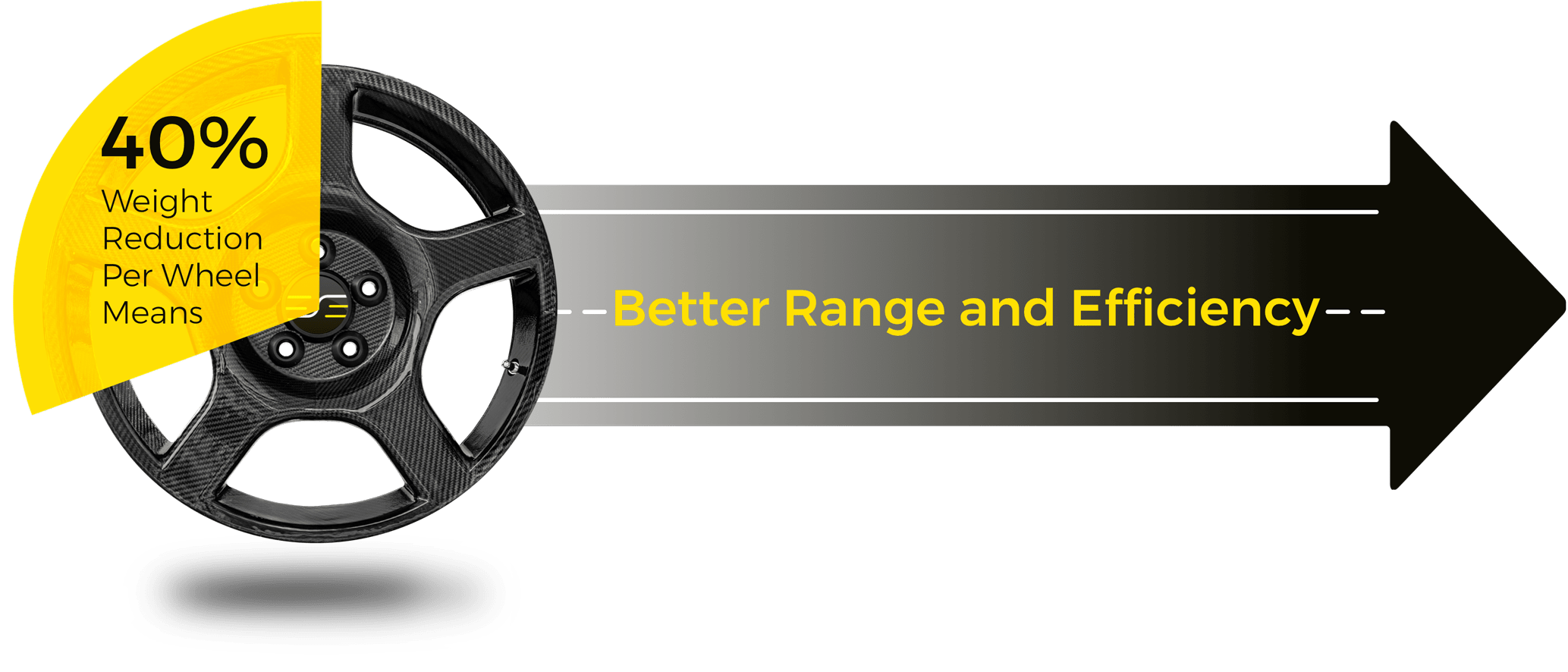

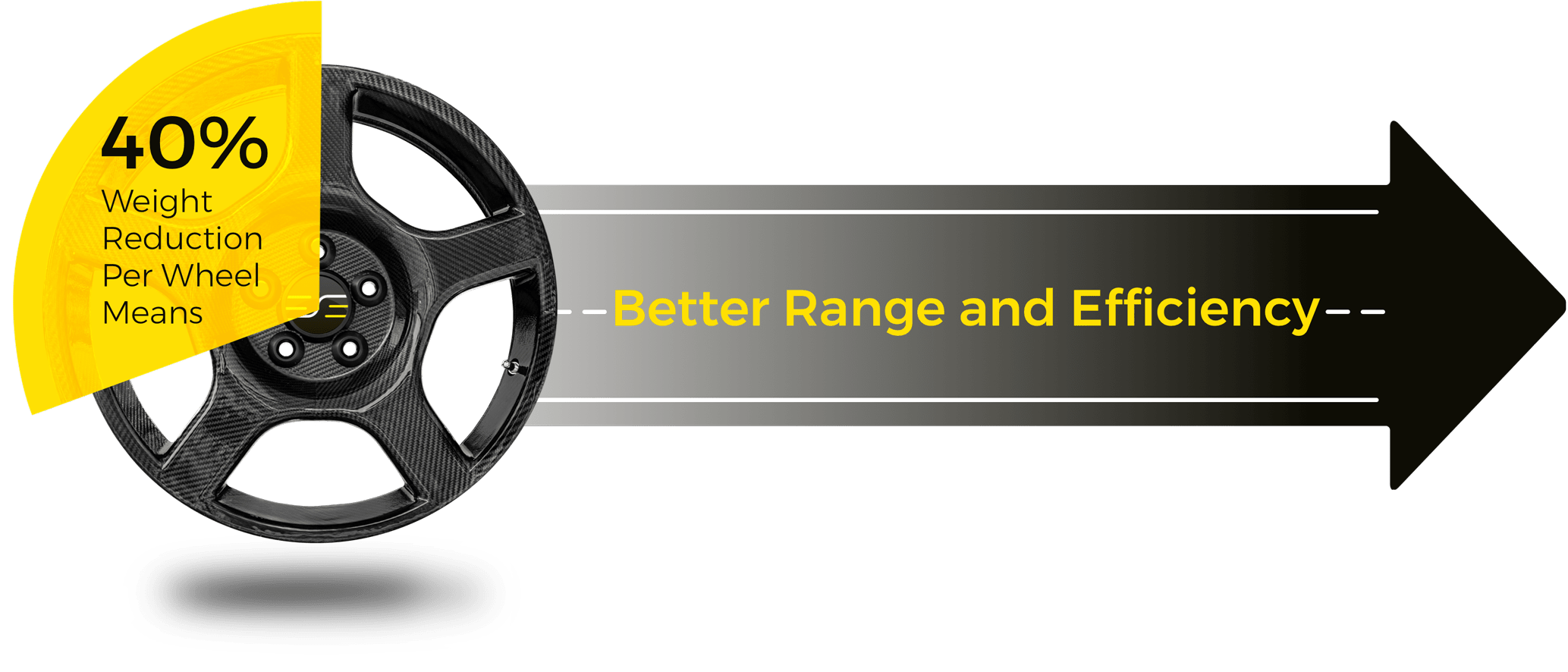

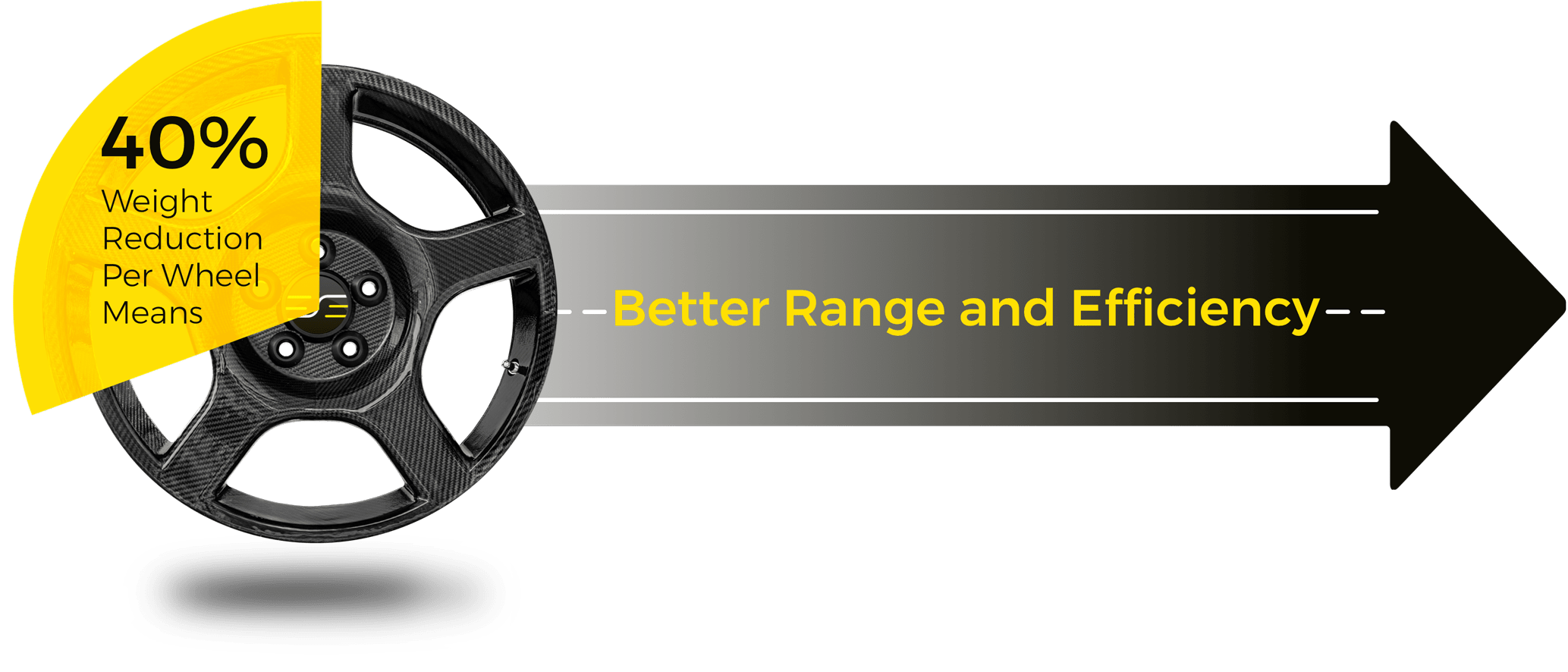

Increased Range

When it comes to today’s electric vehicles, range is THE all-important statistic. Since heavier objects require more energy to both start and stop, every pound of weight saved leads directly to better range and efficiency. At up to a 45% weight reduction per wheel, the E2 carbon fiber wheel will help you go further every day.

Eco-Friendly

The shift toward environmental concerns has led to a transformation in automotive design and engineering that is efficient, while remaining well-performing, attractive and relevant. No material embodies all of these characteristics more than carbon fiber. Carbon fiber also has very high corrosion resistance when compared with aluminum and steel, so carbon fiber wheels will outlast their counterparts.

I just returned from an 850-mile road trip in my Model S. The E2s handled beautifully – on the highway, over back roads, even gravel roads. And they definitely got looks from other Tesla owners at the Supercharger stations. There just aren’t other wheels out there like the E2s!